Material Health:

Metal Fabric for Modern Healthcare Design

Call now 410-901-8429

Metal fabric can help construct positive patient experiences

Balancing Safety With Biophilia

Therapeutic environments that include access to nature, daylight, and fresh air can reduce anxiety, ease depression, support cognitive function, and aid in healing. Woven metal fabric provides a flexible medium to bridge outdoor access with applications in interior design, mid-door creation, and rooftop activation.

METAL MESH SUPPORTS PATIENT SAFETY AND WELL-BEING BY:

- Expanding the building footprint through enclosed mid-door and safe rooftop spaces

- Meeting stringent performance standards for cleaning, maintenance and durability

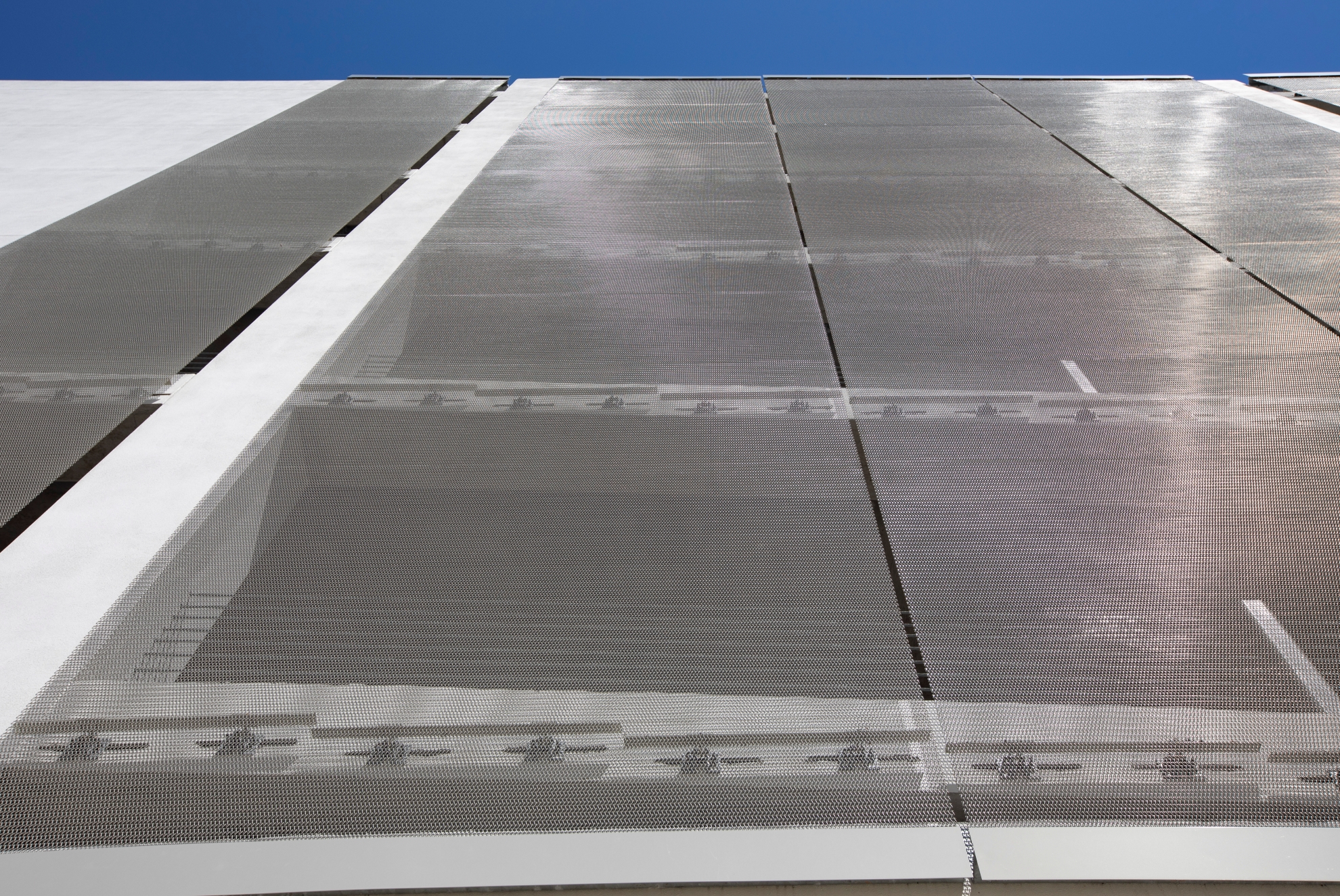

- Providing sunshading over windows or glass façades without obstructing views

- Enabling airflow while maintaining safety as railing infill or fall protection along rooftop perimeters

- Providing an array of color coatings, etching, and printing options to incorporate branding, wayfinding, or calming art features

Safe Materials For Safe Spaces

Behavioral health facilities, whether new or existing, are required to meet comprehensive accreditation standards to ensure that the risks to patient safety are minimized. Principles that support patient safety strategies avoid systems, assemblies and materials that can be weaponized, yield sharp edges, or provide ligature points in all locations accessible to patients.

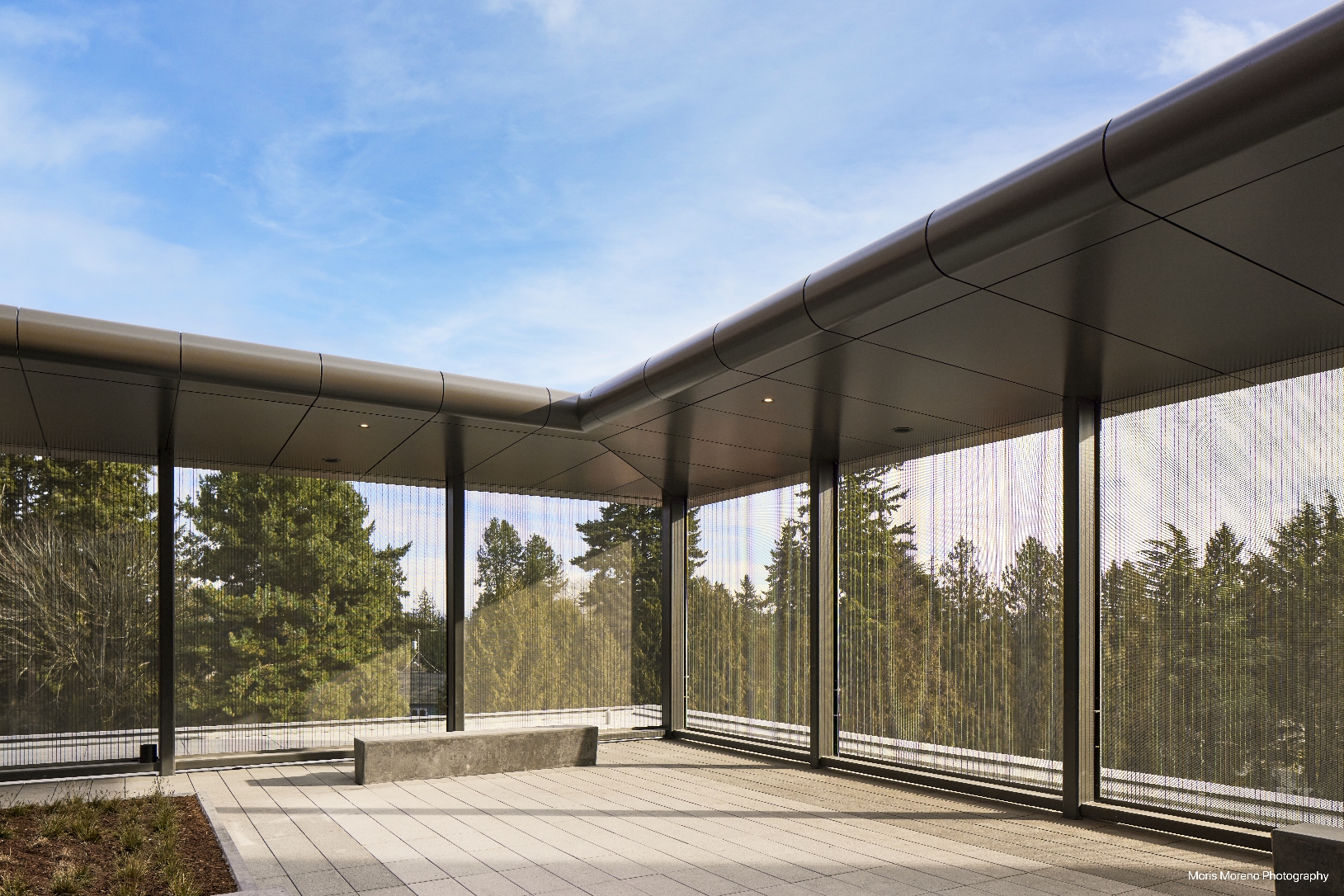

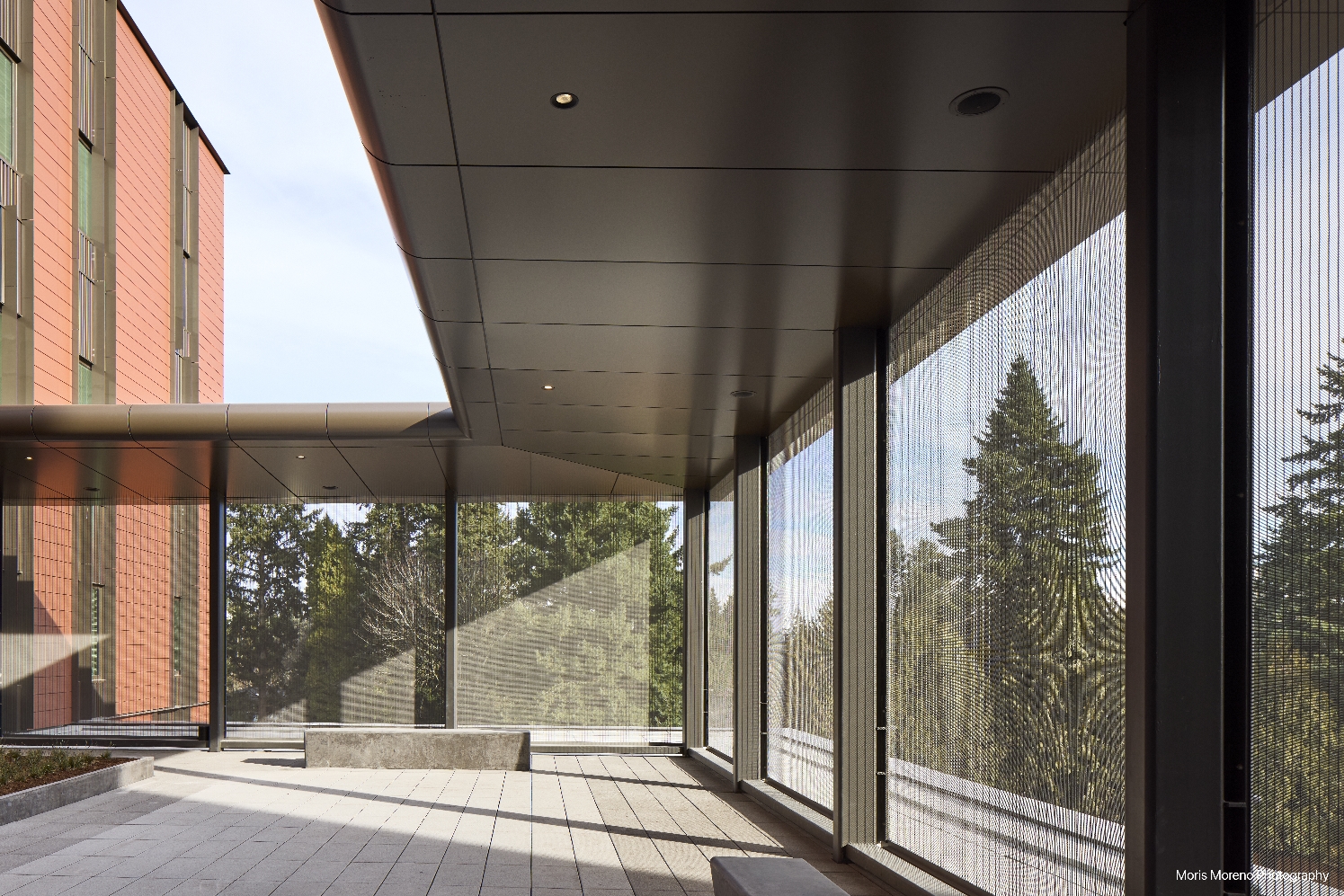

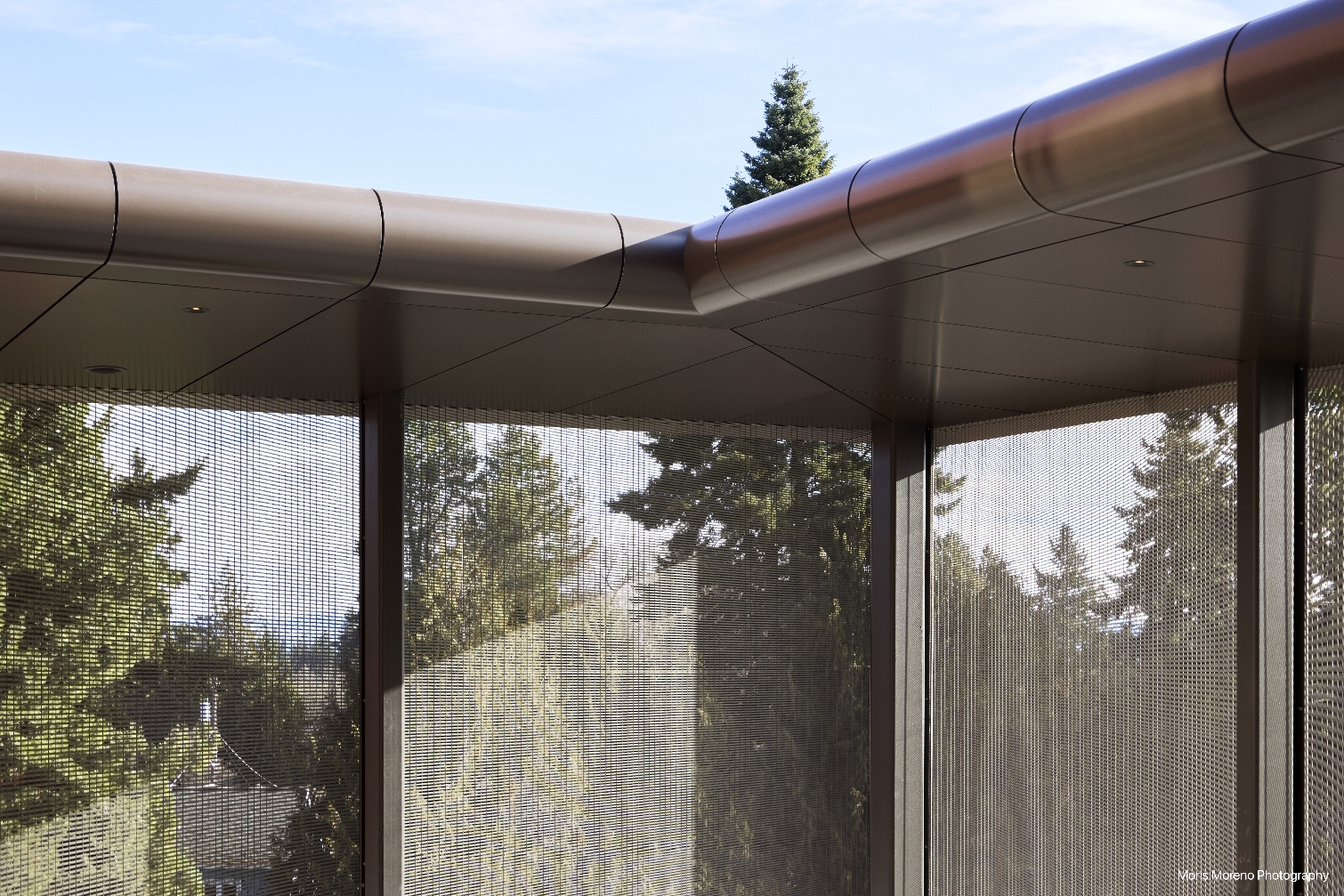

University of Washington Behavioral Health Center, Seattle WA

With a mission to heal and uplift, the University of Washington worked with architecture firm SRG Partnership to maximize inpatient safety and minimize the chances of self-inflicted injury. Using a weave with minimal open space, metal fabric was specified for biophilic security screening in a courtyard terrace. The product provides a blend of transparency and density while eliminating gaps or voids between the mesh material and the structure. This reduces the risk of stuck fingers, ligature, material sabotage, and damage related to human interaction with the screens. The weave is 44% transparent so ventilation, sunlight and views of surrounding greenery are uninhibited. Patients can absorb all the benefits of the outdoors while also being safe and secure – without feeling imprisoned.

University of Kansas Behavioral Health

At the University of Kansas Behavioral Health Center, located in Kansas City KS, Cannon Design of St Louis, MO specified metal fabric for an outdoor courtyard enclosure. Combined with trees and greenery on both sides of the screening, the space is safe while promoting patient well-being.

Products used in this industry

View allFAQ

-

What is the maximum length and width of the mesh?

Maximum length and width are highly dependent on the pattern and whether a weave is rigid or flexible. In the case of flexible meshes, maximum width can span up to 26 feet. Typical length is approximately 100 feet though longer lengths are possible and should be discussed with your sales representative. Rigid or PC meshes tend to have a maximum width of 101 inches. Visit our Product Gallery where you can find specifications for each product.

-

What is your material made of?

GKD’s high-quality woven metal fabrics and innovative attachment systems are crafted of non-corroding, high-grade AISI Type 316 stainless steel. In addition to stainless steel, other materials, such as copper, bronze, and aluminum are available based on function and aesthetics and may require maintenance protocols specific to those materials. Download product spec sheet here.

-

How are panels attached to the building?

Our role as the pioneer of the metal fabric category means that while we have developed a broad range of weave patterns, we have also pioneered a series of attachment methods that ensure optimal results and above all, safety. Please review our Attachment Solutions to learn about the various attachment methods available.

-

Does the material meet or help LEED qualifications?

Using GKD metal fabrics can contribute to LEED points under the Energy and Atmosphere, Material and Resources, Indoor Environmental Quality, Innovation and Design and Site Selection categories. GKD’s line of stainless steel metal fabrics underscores the company’s environmental commitment:

- The stainless steel used in GKD metal fabrics contains greater than 60% post-industrial and post-consumer content recycled material.

- During manufacturing, 100% of the scrap metal material is recycled.

- Because the mesh is constructed of stainless steel or other non-degrading alloys, there is no timeframe for removal or replacement except in the case of remodeling, renovation or changing customer needs. However, if the material is removed, GKD metal fabric is 100% recyclable.

Download this pdf to learn more: Sustainability and LEED Potential Using Stainless Steel Metal Fabrics

-

Does metal mesh meet fall protection requirements?

GKD metal fabrics are an ideal solution for safety and security. For railing or balustrade infill for fall protection, they provide security while retaining a light and graceful presence. The material’s flexibility also facilitates its use on more complex, organic designs. Download this pdf to learn more: Safety Made of Metal Mesh

-

Does metal fabric help with heat gain or loss on a building?

GKD metal fabrics offer excellent solar radiation properties. They combine good to excellent solar protection characteristics while allowing uninhibited views to the outside – particularly when the sun is high in the sky. When it is low in the sky during winter, solar heat gains can be achieved, depending on the type of glazing used. To learn more about solar protection using a metal fabric façade, download Solar Protection with Metal Mesh.

-

Where is your material made?

We manufacture on four continents, with primary metal fabric manufacturing conducted here in the United States at our facility in Cambridge, MD. Contact us to be connected with a rep in your area.